C402b fuel system

Join Date: May 2004

Location: 'Stralia!

Age: 47

Posts: 491

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, now thats going back a few years!

By the time it had gotten to me, it had long since lost the tape deck. I think these days its lucky if it even has seats...

By the time it had gotten to me, it had long since lost the tape deck. I think these days its lucky if it even has seats...

Burn Wing Locker or Aux tanks first?

Where did the term slipper tank come from?

Google slipper tank and all the references are about tanks mounted externally on pylons being called slipper tanks.

Cessna 300 and early 400 series aircraft have "Wing Locker Tanks".

The question of which to burn first is actually something of a dilemma and probably depends on what kind of failure you are going to have on the day, engine or electrical.

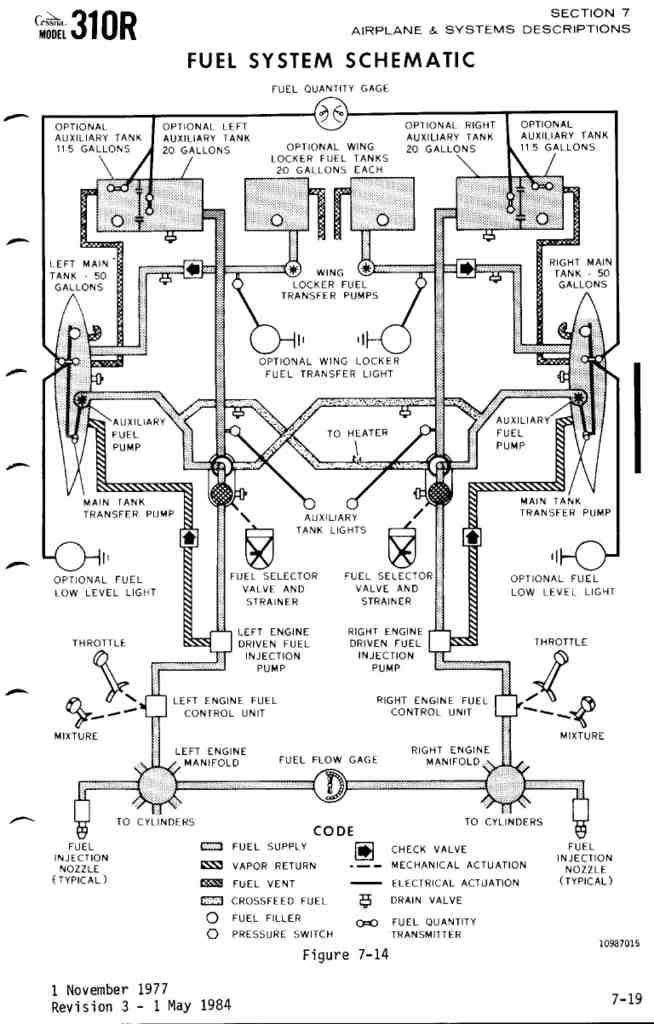

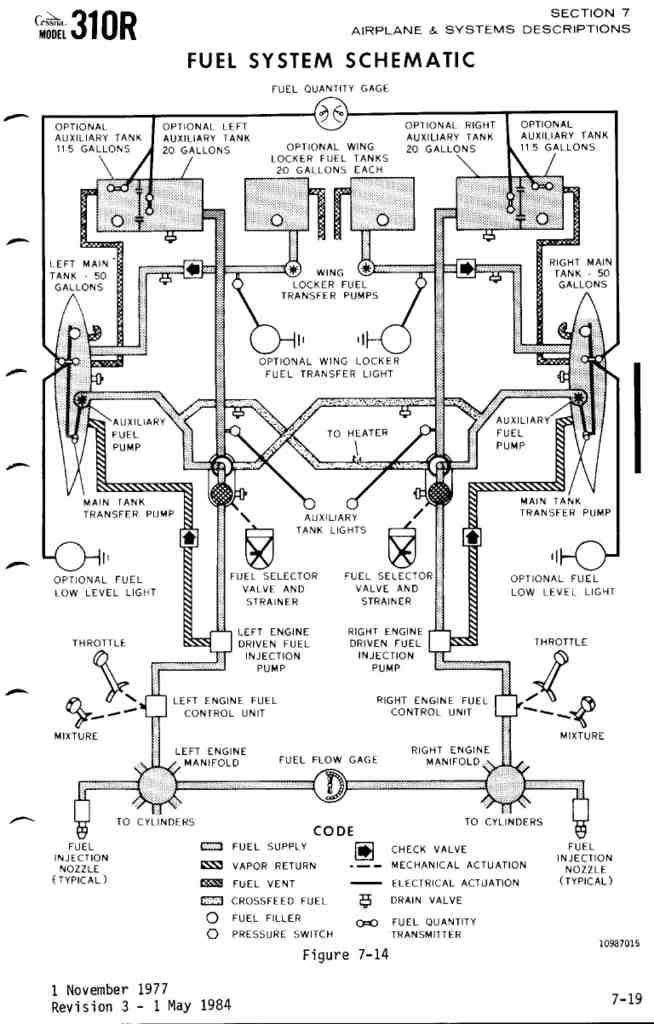

I would use the Auxiliary tanks first because in the event of an engine failure the fuel in the aux tank on the side of the dead engine becomes unmovable in 310's and 402/A/B's due to the fact there is NO FUEL PUMP associated with the Aux tanks except for the engine driven pump. In a 421B there is an electric pump for the Aux tank and I suppose it MIGHT be possible to move some but I never had reason to attempt it The following schematic is for the 310R but is identical to the tip tanked 401's and 402's.

Compare it with the schematic for the 421 in reply #8 and notice the absence of electric fuel pumps in the Aux fuel line between the tanks and the engine driven pump in this diagram.

Without an electric pump, fuel in the aux tanks on the side of a dead engine is just dead weight and located in the outer part of the wing, not exactly where you'd want it with an engine out especially if you're going to have a long way to fly and are going to end up light on fuel on the live side.

This brings up something else to beware of, obviously for the same reason you'd want to crossfeed the main tank fuel from the dead side to the live engine. Remember where the excess fuel if any is going to go, into the tip tank on the live engine side so watch you don't start pumping fuel overboard there while crossfeeding.

PLovett

The capacitance type fuel sensors in later Cessna twins are very accurate when they are working, but I refer you to,

http://www.atsb.gov.au/publications/...200706444.aspx

Ok, a question for you all.

You are somewhere in the bush in a 402C and one fuel gauge is inop.

You can't take a full fuel load but you do need to make sure you have the same amount in both tanks, how could you determine that?

You hunt around the aircraft in all the dim dark recesses and all you come up with is a pair of womens lacy underwear, a plumb bob, a fairly long length of plastic tubing and some old pieces of floor board.

Google slipper tank and all the references are about tanks mounted externally on pylons being called slipper tanks.

Cessna 300 and early 400 series aircraft have "Wing Locker Tanks".

The question of which to burn first is actually something of a dilemma and probably depends on what kind of failure you are going to have on the day, engine or electrical.

I would use the Auxiliary tanks first because in the event of an engine failure the fuel in the aux tank on the side of the dead engine becomes unmovable in 310's and 402/A/B's due to the fact there is NO FUEL PUMP associated with the Aux tanks except for the engine driven pump. In a 421B there is an electric pump for the Aux tank and I suppose it MIGHT be possible to move some but I never had reason to attempt it The following schematic is for the 310R but is identical to the tip tanked 401's and 402's.

Compare it with the schematic for the 421 in reply #8 and notice the absence of electric fuel pumps in the Aux fuel line between the tanks and the engine driven pump in this diagram.

Without an electric pump, fuel in the aux tanks on the side of a dead engine is just dead weight and located in the outer part of the wing, not exactly where you'd want it with an engine out especially if you're going to have a long way to fly and are going to end up light on fuel on the live side.

This brings up something else to beware of, obviously for the same reason you'd want to crossfeed the main tank fuel from the dead side to the live engine. Remember where the excess fuel if any is going to go, into the tip tank on the live engine side so watch you don't start pumping fuel overboard there while crossfeeding.

PLovett

I happpen to be flying a 402C at the moment where the gauges have been proven to be accurate to within 5 to 10 litres and I am talking about the original gauges.

http://www.atsb.gov.au/publications/...200706444.aspx

Ok, a question for you all.

You are somewhere in the bush in a 402C and one fuel gauge is inop.

You can't take a full fuel load but you do need to make sure you have the same amount in both tanks, how could you determine that?

You hunt around the aircraft in all the dim dark recesses and all you come up with is a pair of womens lacy underwear, a plumb bob, a fairly long length of plastic tubing and some old pieces of floor board.

Use the plumb bob + floorboards to get the a/c laterally level. Connect the tubing between the tanks. Gravity will cause the fuel tanks to self-level given enough time.

I suppose the ladies underwear is to wear while waiting for the above to finally finish. You did say I was alone in the bush, didn't you?

I suppose the ladies underwear is to wear while waiting for the above to finally finish. You did say I was alone in the bush, didn't you?

Join Date: May 2002

Location: Permanently lost

Posts: 1,785

Likes: 0

Received 0 Likes

on

0 Posts

Peter Fanelli

Thank you for the link.

Whilst the gauges in the aircraft I am flying are accurate (at the moment) I do not rely on them alone. The aircraft is equipped with a Shadin Fuel Flow meter and because I normally work with a default fuel setting, I know where that level is on the mesh filter in the tanks.

In my previous job I flew 402Cs where the gauges were anything but accurate (they also had Shadin meters) but because I was often having to fly with minimum fuel it became a real art form to work out actual fuel loads. Tended in those cases to always take the lower, gauge or Shadin as the figure which probably led to an increasing fuel load over time but every so often you would get a flight where you could fill the tanks and start from a known figure again.

Thank you for the link.

Whilst the gauges in the aircraft I am flying are accurate (at the moment) I do not rely on them alone. The aircraft is equipped with a Shadin Fuel Flow meter and because I normally work with a default fuel setting, I know where that level is on the mesh filter in the tanks.

In my previous job I flew 402Cs where the gauges were anything but accurate (they also had Shadin meters) but because I was often having to fly with minimum fuel it became a real art form to work out actual fuel loads. Tended in those cases to always take the lower, gauge or Shadin as the figure which probably led to an increasing fuel load over time but every so often you would get a flight where you could fill the tanks and start from a known figure again.

My five cents worth

On the two 402B’s that I have flown, the fuel selector could freeze when operating at approx minus 16 d C. Use forethought when flying in or towards these temperatures or you may be unable to switch between auxies, mains or crossfeed until reaching a warmer altitude.

Beware that the wing locker fuel pumps have been known to not transfer fuel until really wet on descent - even if you do keep the pumps wetted with fuel on the ground.

The ball valve system in the 402B fuel selector can stick, which may cause you to be on a different tank than the tank that the fuel selector is pointing too. Cycling fuel selectors from off, main, auxie, txfr and back during a pre-flight in my opinion is a good idea.

The wing locker vent is pressure sensitive. When filling wing locker tanks (esp when the engine is hot) 1. try not to spill fuel over the turbo 2. if filling to the top, flow the last few litres at a slower rate to equalise the inner and outer tank pressures and or 3. leave the tank caps off until you finish your walkaround; then replace the caps ! If fuel is p*%sing from the vent after you have re-fueled, switching the txfr pump on for a few seconds with the fuel cap off stops the overflow in a few seconds.

! If fuel is p*%sing from the vent after you have re-fueled, switching the txfr pump on for a few seconds with the fuel cap off stops the overflow in a few seconds.

Show Airmanship and avoid running both auxie tanks dry at the same time .

.

Keep those landing light CB’s engaged in flight, esp on descent and landing (ref. ‘ticka’ pumps)

Spotlight – “are ya feeling lucky? Well are ya?” If there was no other operational significance, I would start with transferring wing locker or auxie fuel depending on which failure I would think I’d be more likely occurring on the day. However, consider that only the mains and auxies have quantity indicators.

If it were possible, when fuelling, I would divide the fuel quantity between auxies and wing lockers so that if I had an engine failure, I would have enough remaining fuel in the main and wing locker and the opposite side to get to a destination, or if I had an electrical failure, I would have enough fuel in the mains and auxies to fly to a destination.

Now if only you could fill all tanks and carry useful cargo and not reach MTOW would the 402b system be anywhere as good as an AeroCommander fuel system.

On the two 402B’s that I have flown, the fuel selector could freeze when operating at approx minus 16 d C. Use forethought when flying in or towards these temperatures or you may be unable to switch between auxies, mains or crossfeed until reaching a warmer altitude.

Beware that the wing locker fuel pumps have been known to not transfer fuel until really wet on descent - even if you do keep the pumps wetted with fuel on the ground.

The ball valve system in the 402B fuel selector can stick, which may cause you to be on a different tank than the tank that the fuel selector is pointing too. Cycling fuel selectors from off, main, auxie, txfr and back during a pre-flight in my opinion is a good idea.

The wing locker vent is pressure sensitive. When filling wing locker tanks (esp when the engine is hot) 1. try not to spill fuel over the turbo 2. if filling to the top, flow the last few litres at a slower rate to equalise the inner and outer tank pressures and or 3. leave the tank caps off until you finish your walkaround; then replace the caps

! If fuel is p*%sing from the vent after you have re-fueled, switching the txfr pump on for a few seconds with the fuel cap off stops the overflow in a few seconds.

! If fuel is p*%sing from the vent after you have re-fueled, switching the txfr pump on for a few seconds with the fuel cap off stops the overflow in a few seconds.Show Airmanship and avoid running both auxie tanks dry at the same time

.

.Keep those landing light CB’s engaged in flight, esp on descent and landing (ref. ‘ticka’ pumps)

Spotlight – “are ya feeling lucky? Well are ya?” If there was no other operational significance, I would start with transferring wing locker or auxie fuel depending on which failure I would think I’d be more likely occurring on the day. However, consider that only the mains and auxies have quantity indicators.

If it were possible, when fuelling, I would divide the fuel quantity between auxies and wing lockers so that if I had an engine failure, I would have enough remaining fuel in the main and wing locker and the opposite side to get to a destination, or if I had an electrical failure, I would have enough fuel in the mains and auxies to fly to a destination.

Now if only you could fill all tanks and carry useful cargo and not reach MTOW would the 402b system be anywhere as good as an AeroCommander fuel system.

Join Date: Mar 2001

Location: Perth

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

Peter,

As long as you had sufficient spaces in the main tanks to hold half the capacity of the aux, otherwise you would pump it overboard.

So, fly for an hour on the mains, then use the aux's, as per the POH pretty much and you'll have no problems.

Slipper tank, AKA Nacelle tank, i have flown 15 odd different aircraft with these fuel systems, only one had the Nacelle tank.

I would use the Auxiliary tanks first because in the event of an engine failure the fuel in the aux tank

So, fly for an hour on the mains, then use the aux's, as per the POH pretty much and you'll have no problems.

Slipper tank, AKA Nacelle tank, i have flown 15 odd different aircraft with these fuel systems, only one had the Nacelle tank.

Join Date: Dec 2007

Location: Antartica

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

Como esta

402 Cessna Argentina not to sure what your trying to find out about the 402B fuel system but at the end of the day you shouldn’t trust information or diagrams off a rumour network to make repairs on your fuel system. Get a copy of the Service/Parts Manual. Since a lot of aircraft crash because of fuel problems I suggest getting it done right.

Who ever did your training on the 402b should have given you a complete run down on the fuel system and I applaud you if your doing extra study into it, as I am sure it could trip up even an experienced pilot

Adios

402 Cessna Argentina not to sure what your trying to find out about the 402B fuel system but at the end of the day you shouldn’t trust information or diagrams off a rumour network to make repairs on your fuel system. Get a copy of the Service/Parts Manual. Since a lot of aircraft crash because of fuel problems I suggest getting it done right.

Who ever did your training on the 402b should have given you a complete run down on the fuel system and I applaud you if your doing extra study into it, as I am sure it could trip up even an experienced pilot

Adios

Join Date: May 2005

Location: WA

Posts: 65

Likes: 0

Received 0 Likes

on

0 Posts

I remember a Darwin based 402 running a tank dry about 8 years ago, It turned out to be loose screws on the fuel selector housing, valve was not pointing where it should of, the pilot landed at Tindal I think,

Join Date: Jan 2001

Location: Australia

Posts: 725

Likes: 0

Received 0 Likes

on

0 Posts

I remember a Darwin based 402 running a tank dry about 8 years ago, It turned out to be loose screws on the fuel selector housing, valve was not pointing where it should of, the pilot landed at Tindal I think,

http://www.atsb.gov.au/publications/...200001827.aspx

As described in my previous post, when C400 types were the mainstay of air north, we made the fuel selections during runups, each engine drawing fuel from each available tank, then momentarily OFF, then back to mains.

Then orders came from above, do not make those non standard fuel selections in runups. The engineers are complaining that you are U/S'ing aeroplanes after they fail a test that is not in the POH

Just before those instructions made it into flight standing orders, a pilot took a 402C out of Tindal that had a few recent issues with the fuel system. Pilot did runups to new policy. Start on mains, select crossfeed and ensure it runs ok, then return to mains.

Only problem was, the selector valve mechanism was worn. The selector handle was pointing at MAIN for both engines, but both motors were feeding off the left tank. So there was two hours fuel in the aeroplane, but only one hours available to feed the motors for a one hour TN-DN flight.

The pilot proceeded to destination. The left motor cut due fuel starvation in the landing roll, and the right motor cut due fuel exhaustion as it taxiied off the runway. The right motor lasted a bit longer due to a little more fuel available in the crossfeed plumbing!

Last edited by ITCZ; 29th Jan 2008 at 18:12.

Join Date: Dec 2007

Location: Antartica

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

Only problem was, the selector valve mechanism was worn.

Best to change the Orings on a regular basis , almost every time the selector is out ....no point being lazy

PLovett I wouldn't put all your faith in Shadin fuel computers either as they do have little problems including pilot finger trouble and also electrical spikes/surges don't always do them the world of good either.

Join Date: May 2002

Location: Permanently lost

Posts: 1,785

Likes: 0

Received 0 Likes

on

0 Posts

Stationaire8

That is not what I said.

I use 3 separate methods and cross check between them: visual check of the tank (when filled to the default setting), the gauges and the Shadin. On arrival at a destination I have an idea of what should be in the tanks and that is what I initially look for on the gauges and the Shadin. I then confirm (or get worried ) when I refuel.

) when I refuel.

I wouldn't put all your faith in Shadin fuel computers either

I use 3 separate methods and cross check between them: visual check of the tank (when filled to the default setting), the gauges and the Shadin. On arrival at a destination I have an idea of what should be in the tanks and that is what I initially look for on the gauges and the Shadin. I then confirm (or get worried

) when I refuel.

) when I refuel.

Join Date: Jan 2004

Location: En Zud

Age: 52

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

Hot starts

QuoteOne other issue i have had with the C402/C310 is hot starting.

"The Left and Right Landing lights circuit breakers also power the ticker pumps ( these are located on the bottom side of the main fuel tank pods, turn the master on and you should hear them tick tick ticking ).

When priming a hot engine, i have had more sucess by opening the cct breaker during the start and priming the fuel system with the fuel pumps in the "HI" position.

Ensure the cct breakers are closed after start.

I have had little sucess using the "prime" function switch, surely someone else here would have some solid advice on how to best use the prime function."

Hi LHRT,

Most of what you say about the 310/402 fuel system is spot on Very good info indeed!

Very good info indeed!

However, the info on start technique you state above really does need some mention.

Forget about circuit breakers and ticker pumps etc.. what the IO520 wants is fuel. Through the system that is!

It (B58,C310,C402,C404 etc etc) requires fuel to flow through the system for at least 30 secs to cool the pump and fuel control unit to prevent the fuel boiling (vapour). Check the B58 POH, it almost says just that.

So, the best start method to use (as per the manufacturer really):

Throttle open, Mixture lean, Pumps High for 30 secs, pumps off, mixture rich, throttle 1 inch or so, start!

C402,404,310 use a tickle on the primer as you crank, you WILL get a perfect start every time.

This method is what the manufacturer recommends, and is also the SOP at Skytrans and Westwing who fly these things every day.

"The Left and Right Landing lights circuit breakers also power the ticker pumps ( these are located on the bottom side of the main fuel tank pods, turn the master on and you should hear them tick tick ticking ).

When priming a hot engine, i have had more sucess by opening the cct breaker during the start and priming the fuel system with the fuel pumps in the "HI" position.

Ensure the cct breakers are closed after start.

I have had little sucess using the "prime" function switch, surely someone else here would have some solid advice on how to best use the prime function."

Hi LHRT,

Most of what you say about the 310/402 fuel system is spot on

Very good info indeed!

Very good info indeed!However, the info on start technique you state above really does need some mention.

Forget about circuit breakers and ticker pumps etc.. what the IO520 wants is fuel. Through the system that is!

It (B58,C310,C402,C404 etc etc) requires fuel to flow through the system for at least 30 secs to cool the pump and fuel control unit to prevent the fuel boiling (vapour). Check the B58 POH, it almost says just that.

So, the best start method to use (as per the manufacturer really):

Throttle open, Mixture lean, Pumps High for 30 secs, pumps off, mixture rich, throttle 1 inch or so, start!

C402,404,310 use a tickle on the primer as you crank, you WILL get a perfect start every time.

This method is what the manufacturer recommends, and is also the SOP at Skytrans and Westwing who fly these things every day.

Join Date: May 2000

Location: Australia

Posts: 344

Likes: 0

Received 0 Likes

on

0 Posts

Ticker Pumps

just to set the record straight guys. The ticker pumps do not pump fuel into the fuel lines or pressurise the fuel sytem in any way. What they do is pump fuel from the front of the tank, when in low fuel state, back to the collector box where the main fuel feed is during descent. So don't worry about pulling circuit breakers as it will not serve any purpose. For others who are not quite sure the primer switch and the seperate Hi / Low boost switches actually use the same pump. I assume that the different fuel flow is achieved by regulating the voltage. Good thread though and pretty much spot on.