Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

Missing Negative G Bolts on MAX9

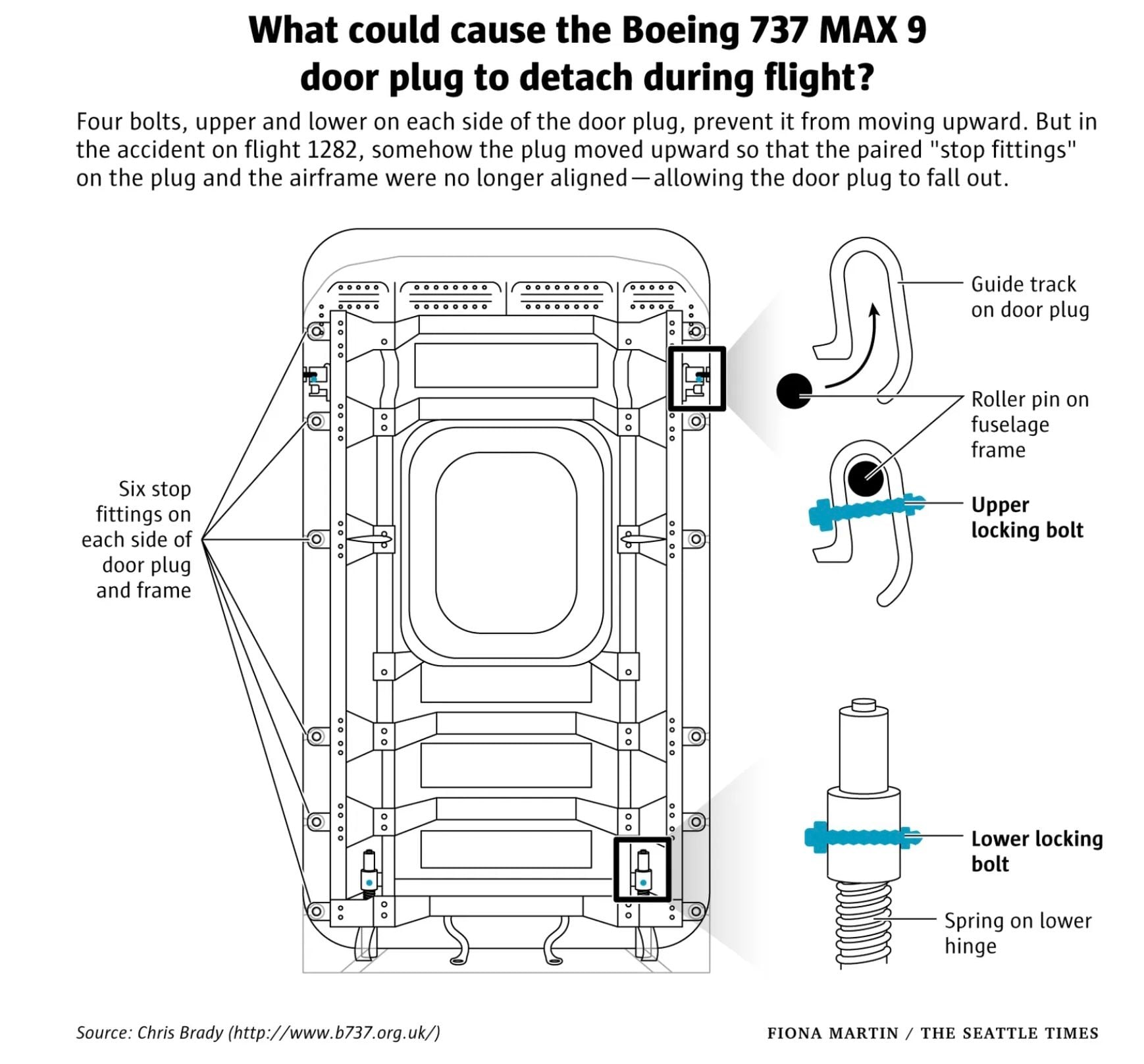

Best illustration and explanation and of plug retention is in Seattle Times at NTSB focus on Boeing, Spirit assembly work after Alaska Airlines blowout | The Seattle Times

Best illustration and explanation and of plug retention is in Seattle Times at NTSB focus on Boeing, Spirit assembly work after Alaska Airlines blowout | The Seattle Times

Join Date: Jan 2024

Location: Cork

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

The assembly is mounted on a spring, so alignment at that point is not a critical factor.

??? The lower locking bolt pair keep the hinge springs from applying 60 lbs of force on the bottom of the plug. With all four locking bolts removed, the door plug moves up 4cm, the stops/pads de-mate and the door plug deploys to the open maintenance position.

Join Date: Nov 2018

Location: VA

Posts: 30

Likes: 0

Received 0 Likes

on

0 Posts

When the lower lock bolts are in place, the lower hinges are effectively the same length. That is when adjustments for alignment would be made, since that is the position it should spend 99% of it's life.

some thoughts, apologies for unseen repeats

Plug seems over-engineered. Why complex hinge, guides and stopper pads when 12 studs/captive bolts with castellated nuts and cotter pins could suffice, redundancy built-in. Not much to inspect except seals and corrosion so infrequent maintenance requirement, can't see labour-saving being significant.

Slainte

Plug seems over-engineered. Why complex hinge, guides and stopper pads when 12 studs/captive bolts with castellated nuts and cotter pins could suffice, redundancy built-in. Not much to inspect except seals and corrosion so infrequent maintenance requirement, can't see labour-saving being significant.

Slainte

A genuine question - the people who design and build these things are generally not stupid but I'm curious about the reasoning.

In the comments following the Dominic Gates article in the Seattle Times that ozaub linked to, above, Gates pops in to reply to a commenter with this:

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

Join Date: Jun 2009

Location: Montreal

Age: 65

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

As a non-aviation engineer, this thought also occurred to me several times through this thread. If the plug is not intended for routine removal, even during maintenance, or intended for future modification to create an active emergency exit, why have springs/hinges etc been fitted at all? Why not simple bolts through the 12 bearing plates, secured/castellated/wired as needed? (I appreciate these may need modified for this but it still seems simpler and more secure than the overly complex arrangement used currently).

A genuine question - the people who design and build these things are generally not stupid but I'm curious about the reasoning.

A genuine question - the people who design and build these things are generally not stupid but I'm curious about the reasoning.

Why don't they bolt together the stop pads and stop fittings? That's because it would change the load paths. Doors are designed not to pick up general fuselage loads, they sort of "float". So if you created bolted connections to the fuselage at 12 points, the door would become primary structure and you would have to redesign local fuselage frames, intercostals, and skins, and add a nontrivial certification item to cover just the plug doors. For design, analysis, and testing, you are potentially looking at 7 figures.

Join Date: Jul 2022

Location: USA

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

In the comments following the Dominic Gates article in the Seattle Times that ozaub linked to, above, Gates pops in to reply to a commenter with this:

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

From the way Gates phrased his reply, it seems that he's talking about SOP. But he also seems confident and we know that he has extremely good contacts and connections at Boeing. At a minimum, what he says should be considered seriously, IMHO.

Join Date: Jul 2022

Location: USA

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

Does he speak for Boeing?

Appears to implicate Spirit directly.

3 previous flights with master caution and cabin pressure warnings on a new AC - by the 3rd occurrence Alaska should have grounded it until they found out exactly why, lessons from MCAS still needed. Scheduling a future inspection and cancelling ETOPS indicates unfit for purpose risk assessment, insufficient regulation/compliance standards. With cabin pressurisation a life-critical system, Boeing, FAA and Alaska all have responsibility.

Slainte

Slainte

Why does the door plug look overdesigned, with heavy machinged members? The main reason is because it works as a curved plate to carry the pressure, which means there is a lot of plate bending in the structure. Baseline fuselage structure works as a pessure vessel with primary loads in tension. Plate bending is structurally inefficient.

Why don't they bolt together the stop pads and stop fittings? That's because it would change the load paths. Doors are designed not to pick up general fuselage loads, they sort of "float". So if you created bolted connections to the fuselage at 12 points, the door would become primary structure and you would have to redesign local fuselage frames, intercostals, and skins, and add a nontrivial certification item to cover just the plug doors. For design, analysis, and testing, you are potentially looking at 7 figures.

Why don't they bolt together the stop pads and stop fittings? That's because it would change the load paths. Doors are designed not to pick up general fuselage loads, they sort of "float". So if you created bolted connections to the fuselage at 12 points, the door would become primary structure and you would have to redesign local fuselage frames, intercostals, and skins, and add a nontrivial certification item to cover just the plug doors. For design, analysis, and testing, you are potentially looking at 7 figures.

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

In the comments following the Dominic Gates article in the Seattle Times that ozaub linked to, above, Gates pops in to reply to a commenter with this:

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

Anyhow, I hope they get the inspection AD sorted soon as I have a couple of flights on these United Max9's starting this weekend.

Those 2 loose bolts in bottom picture of spring hinge assembly does not look to be reassuring QA, I guess unless they were loosened later after incident. Washers not compressed at all

I don't think those are bushings, those are the bolts, and it's interesting. First of all, it looks like the failure mode was tension in these two, not shear. I say it because one looks like it has the head pulled off, and the other broke the end pad while it was pulling through the hole (see the second picture).

I popped the colours in this image to make it easier to see things. The one end pad location where the bolt appears to have lost its head is intact. So end pad was strong enough to pull the head off the bolt. The other end pad, where the bolt still has it's head, is missing. The bolt was strong enough to fracture the end pad in shear/bending.

It's not surprising that those failed in tension. There will be a moment on the fitting when the hinge post is pulling "down" (in the door coord system), putting the top fasteners (these two) in tension and the bottom ones in compression. Except fasteners don't take compression, that goes through contact pressures between the fitting and frame. The bottom bolts probaby failed in shear, bearing tear-out, or prying, or some kind of mixed mode.

On the other side it probably looks similar...maybe? It's hard to predict with wild failure processes like this. Some have theorized some or all of these 8 bolts were missing (4 fwd 4 aft) but I'm pretty sure the NTSB would have mentioned that by now.

The grey square where the fitting contacted the frame web is sealant.

I popped the colours in this image to make it easier to see things. The one end pad location where the bolt appears to have lost its head is intact. So end pad was strong enough to pull the head off the bolt. The other end pad, where the bolt still has it's head, is missing. The bolt was strong enough to fracture the end pad in shear/bending.

It's not surprising that those failed in tension. There will be a moment on the fitting when the hinge post is pulling "down" (in the door coord system), putting the top fasteners (these two) in tension and the bottom ones in compression. Except fasteners don't take compression, that goes through contact pressures between the fitting and frame. The bottom bolts probaby failed in shear, bearing tear-out, or prying, or some kind of mixed mode.

On the other side it probably looks similar...maybe? It's hard to predict with wild failure processes like this. Some have theorized some or all of these 8 bolts were missing (4 fwd 4 aft) but I'm pretty sure the NTSB would have mentioned that by now.

The grey square where the fitting contacted the frame web is sealant.

If one believes that the door plug cannot open without moving up, and one believes that the stop bolts should prevent it moving up, then any other fastener damage is likely caused the the severe airloads (outflow and slipstream) after the plug opened and is not the cause of it opening.

The bottom hinges could have been completely missing from the aircraft. That would make the door plug harder to install but that defect would not enable the door plug to open if the upper two locking bolts were in place and the stop fittings overlapped as intended.

Probably obvious to most but seems to be causing a diversion from the main question. Were the locking bolts installed?

The bottom hinges could have been completely missing from the aircraft. That would make the door plug harder to install but that defect would not enable the door plug to open if the upper two locking bolts were in place and the stop fittings overlapped as intended.

Probably obvious to most but seems to be causing a diversion from the main question. Were the locking bolts installed?

They havent found any of the bolts according to the last NTSB news conference i watched & the spring is also missing.

For me, apart from some structure failing which again the ntsb has said wasnt the case the only way that plug can move upward & out of the hole in the fuselage is for those 4 bolts to be missing.

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

...Therefore, it is likely there is always some force against the retention bolts, it always negative g to the plug. Force on the upper bolts is going to depend on tolerances and dimensions and adjustments. Force on the lower bolts is always present because the bolts are holding the springs compressed through the Hinge Spring Guide.

Join Date: Jul 2021

Location: FL95

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

In the comments following the Dominic Gates article in the Seattle Times that ozaub linked to, above, Gates pops in to reply to a commenter with this:

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

"That speculation is not true. Renton does not remove and reinstall the door plug."

As many here know, Gates has been covering Boeing for a couple of decades and won a Pulitzer for coverage of MAX MCAS saga.

I'm convinced that the plug was removed, outside of procedure, from the tool marks I see in the United photos. Now, as to who removed it in such a manner and, regardless of what's printed on someone's MRO website or the last NTSB presser, I think we need to get there fast. The more IQ points thrown at it, the better. My guess is it's something simple, like someone had the bright idea to get their pneumatic hose to a location faster and "quickly" removes these plugs.

That guide track, roller, locking pin assembly, we were looking at about a dozen times in this thread isn't from the united plane with the loose hinge bolts, is it? The inlet of this guide track is indeed rather banged up for single installation and zero deinstallation.

Join Date: Aug 2007

Location: Sweden

Age: 46

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

It is doubtful that the springs are strong enough to lift the plug up and out of the closed position on their own. Otherwise the plug couldn't be closed and stop bolts installed without keeping downward pressure on the plug. That being the case, when the plug is closed the weight of it is carried by both the upper guides and lower springs, but essentially its located by the upper guides aligning the lower stop bolt holes perfectly for installation of the lower stop bolts. All of this is to say that the lower hinge slide fittings resist the springs upward force with the help of the weight of the plug. Therefore the lower stop bolts would have no shear force to resist unless an additional external upward force was applied to the plug. Same goes for the upper stop bolts.

When the door plug was developed, it was simpler just to keep the springs in situ, though of course they now offset a higher proportion of the door plug's weight (assuming the same degree of compression).